Tube Fitting Division

We supply all of your tube fitting needs through trusted suppliers. These are listed below according to manufacturer.

Parker is one of the leading manufacturers of tube fitting products.

Parker CPI™ / A-LOK® Instrumentation Tube Fittings are designed as leak-free connections for process, power and instrumentation applications. These single and two ferrule fittings are manufactured to the highest quality standards and are available in a broad range of sizes, materials and configurations.

Male Connector

Male Elbow

NPT Male Branch Tee

Features

The Parker CPI™ / A-LOK® tube fitting has been specifically designed for use on instrumentation, process and control systems, analyzers and environmental equipment employed in chemical, petroleum, power generating and pulp and paper plants. CPI™ / A LOK® fittings have also been used extensively in other applications and industries wherever high reliability and quality are required.

Torque

Parker CPI™ / A-LOK® tube fittings do not twist the tubing during installation. CPI™ / A-LOK® ferrule designs assure that all make and remake motion is transmitted axially to the tubing. Since no radial movement of the tubing occurs, the tubing is not stressed. The mechanical integrity of the tubing is maintained.

Materials

Parker CPI™ / A-LOK® fittings are available as standard in Heat Code Traceable, 316 stainless steel. Other materials include steel, brass, aluminum, nickel-copper, Hastelloy C®, Alloy 600, Titanium, 6Mo, Incoloy 625 and 825. Straight fittings are machined from cold finished bar stock and shaped bodies are machined from close grain forgings. The raw materials used fully conform to the chemical requirements listed in Specification Table 1 found on page 6. For nuclear and other critical applications, stainless steel CPI™ / A-LOK® fittings are readily available with documented heat code traceability.

No Distortion

In make-up, there is no undue force in an outward direction to distort the fitting body or ferrules to cause interference between the ferrules and nut. This assures that the nut will back-off freely for disassembly and permits a greater number of easy remakes.

Sealing

Positive, reliable connections with Parker CPI™/ A-LOK® fittings have been qualified by exhaustive tests and over four decades of experience in the manufacture of quality tube fittings.

Nomenclature

Parker CPI™ / A-LOK® fitting part numbers are constructed from symbols that identify the size and style of the fitting and material used.

Pipe Fittings/Adapters

Parker Instrumentation Pipe Fittings are designed as leak-free connections for process, power, instrumentation and general plumbing applications. They are manufactured to the highest quality standards and are available in broad ranges of sizes, materials and configurations.

These are standard in steel and brass but other materials may be special ordered. Straight fittings are manufactured from applicable ASTM bar stock specifications shaped fittings are manufactured from close grain forgings.

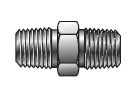

Male Hex Nipple

Street Elbow

Female Cross

Tubing

Parker CPI™ / A-LOK® tube fittings can be used with a wide variety of tubing materials and a broad range of tube wall thicknesses. CPI™ / A-LOK® seals equally well on both thin wall and heavy wall tubing. Tubing and fitting materials should be selected to be compatible with the fluid media. Due to thermal expansion characteristics and chemical stability, the tubing should be of the same material as the fitting. (The exception is brass fittings and copper tubing.)

Stainless Steel Tubing