Instrumentation, Manifolds, and Valves

We supply all of your instrumentation, manifolds, and valves through trusted suppliers. These are listed below according to manufacturer.

Parker is one of the leading manufacturers of instrumentation, manifolds, and valves.

- MPI Medium Pressure Valves

- Precision Metering, Needle, Ball, Check, Plug, and Manifold Valves

- Sample Cylinders

- Sanitary Valves

- Manifold Valves

- R-Max

- IntraFlow™

- Phastite

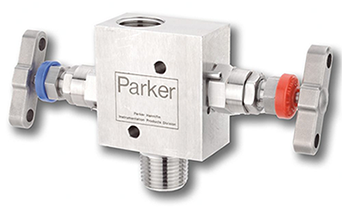

3 Valve Manifold – H Series

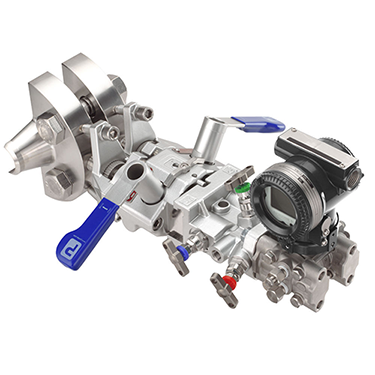

Close Coupled Instrument Mounting Systems (CCIMS)

Parker’s close-coupled valve is designed to improve overall system performance, reliability and safety by eliminating impulse lines and connections. The range includes three main assembly types, each of which can reduce the number of potential leak paths by as much as 85%. Every Parker CCIMS solution offers a choice of instrumentation connection styles, including single ferrule or Parker A-LOK double ferrule compression type end connections, as well as NPT threaded connections.

Markets:

- Oil and Gas Offshore

- Oil and Gas Onshore

- Petrochemical

- Chemical

CCIMS® Flow Measurement

CCIMS® Flow Measurement is a breakthrough solution for direct-mounting differential pressure transmitters to orifice carriers and flanges in a close-coupled installation.

CCIMS® combines an instrument manifold and a piping isolation valve interface giving a simplified modular means of connecting instruments.

The CCIMS® Flow Measurement assembly comprises of:

- Only 5 connections

- Straight through flow path

- Unique ‘PhasFit’ interlocked

Reduced:

- Installation labour time/cost – up to 75%

- Installation problems

- Plant down time, when calibrating instrument

- Problems from impulse lines (no leakage or blocking)

- Potential leak paths – up to 85%

- Cost of ownership

Improved:

- Safety

- Measurement accuracy

- Connection interface

- Easy interlock system

- Orifice mounting system

- Patented PEEK seal system maintains 100% leak tight seal for up to 10,000 psi (689 bar) use

- Available with Primary (Isolation) module or Secondary (Instrument) module (3 or 5 valve)

CCIMS® Monoflange

CCIMS® Monoflange is a breakthrough solution for direct mounting static pressure transmitters in a close-coupled installation.

The close-coupled monoflange combines an instrument manifold integrally into a piping isolation monoflange giving a simplified modular means of connecting instruments.

The CCIMS® Monoflange assembley comprises of:

- Only 2 connections

- Reduced length flow path

Reduced:

- Installation labour time/cost – up to 85%

- Installation problems

- Plant down time, when calibrating instrument

- Problems from impulse lines (no leakage or blocking)

- Potential leak paths – up to 85%

- Cost of ownership

Improved:

- Safety

- Measurement accuracy

- Connection interface

- Up to 10,000 psi (689 bar) use

Markets:

- Oil and Gas Offshore

- Oil and Gas Onshore

- Petrochemical

- Chemical

Applications:

- Chemical injection

- Process to instrument interface

- Gas or light liquid service

Features/Benefits:

- Close coupled

- One piece forged construction

- Shell TAT approval and meets MESC SPE 77/300

- Heat code traceable and NACE compliant materials

- ISO 15848 Class A (HS) and B standards

- Integral two and single ferrule connections, which reduces potential leak paths

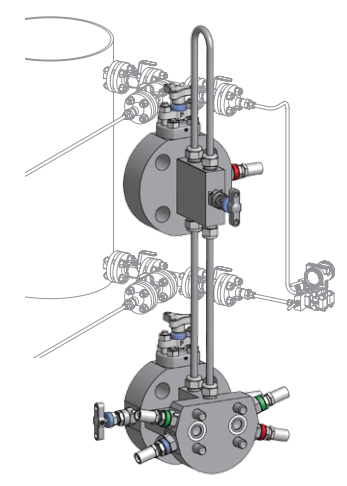

CCIMS® Level-flange

CCIMS® Level-flange is a breakthrough solution for direct-mounting differential pressure transmitters in a close-coupled liquid level installation.

The CCIMS® Level-flange combines an instrument manifold integrally in to a piping isolation monoflange giving a simplified modular means of connecting instruments. The CCIMS® Level-flange is mounted at the bottom of the tank (or wet leg), and allows the

differential pressure transmitter to be directly mounted to the monoflange, and connects the high pressure connection. The low pressure (or dry leg) is connected to a monoflange, which then is connected with a balance line to the CCIMS® Level-flange.

The CCIMS® Level-flange assembly comprises of:

- Only 4 connections

- Shorter length flow path

Reduced:

- Installation labour time/cost – up to 85%

- Installation problems

- Plant down time, when calibrating instrument

- Problems from impulse lines (no leakage or blocking)

- Potential leak paths – up to 85%

- Cost of ownership

Improved:

- Safety

- Measurement accuracy

- Connection interface

CCIMS® Flanged Connector

One piece integral connectors allow the user to switch from piping flange standards to instrument compression with minimal cost and added safety. This solution also eliminates the need for additional connectors.

Outlet connectors are preferable with A-LOK® compression fittings. The use of A-LOK® or inverted A-LOK® removes a potential leak path and reduces assembly and maintenance time, compared to an NPT connection.

Ultra Low Emissions

We can now offer the complete CCIMS® range with our latest valve technology to meet either class ‘A’ or class ‘B’ levels of the ISO 15848 standard for Ultra Low Emissions, as required. This new valve technology helps us provide process instrument interfaces of outstanding integrity to help processing organisations dramatically enhance their LDAR (leak detection and repair) programs.

CCIMS® Enclosure System

The CCIMS® Enclosure System can be supplied fully populated, with manifolds, tubing and electrical heating systems to provide protection for the most demanding site conditions and process applications. Parker will supply completed enclosure solutions to provide frost protection right through to elevated temperature maintenance.

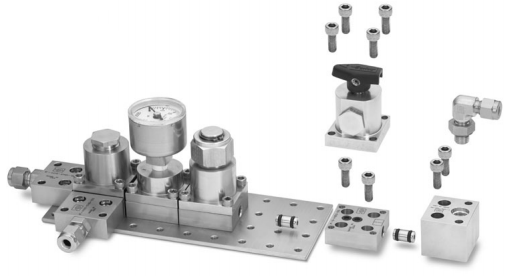

Pro-Bloc®

This manifold range is designed to replace conventional multiple-valve installations currently in use for interface with pressure measuring systems. By combining customer specified valves into a single manifold, the number of leak paths is considerably reduced and the mass of the system is lowered reducing the stresses from loading and vibration. The result of which substantially improves installation and operational safety factors. Reduction in leakage path connections together with a one-piece solution also provides positive installation cost savings.

Tru-Loc:

Mechanical Sealed End Connection Designed specifically for Pro-Bloc end connection security. Extensive tests have proved that end connections locked with the Tru-Loc (PP) end connector locking mechanism give 100% security and prevent end connector movement when disconnecting instruments or connectors. This ensures that the Ball Seat is securely positioned at all times.

Features/Benefits:

- A one-piece integral forging incorporating up to 3 ball valves or mixture of ball and needle design

- Improved safety: leak paths reduced by up to 60%

- Reduced costs: installation and component costs reduced by up to 70%

- Reduced weight: by up to 80%

- Reduced susceptibility to problems caused by vibration

Instrument Outlet Connections

One of the unique features Parker can offer users which can further enhance safety factors is the incorporation of single or twin ferrule compression fittings as an integral part of the outlet connection. Installation of the instrument which require remote positioning will be interconnected using conventional tube and compression fittings, whilst NPT taper threads are accepted as a standard their use involves some form of thread sealant which adds to the complication of instrument performance through contamination within the system. Avoiding these taper thread connections wherever possible reduces this contaminant risk and Parker, being a leading manufacturer of compression type of fittings (which requires no sealant mediums), can incorporate them in the outlet connection, totally eliminating the contamination risk.

H-Series

Parker’s remote and direct mount manifolds are one of the most extensive in the process instrumentation industry and accommodates all types of instrumentation installations, specifications and applications. There is a choice of single-isolate-and-vent, double-isolate-and-vent, double-isolate-and-equalise, and double-isolate-equalise-and-double-vent block configurations. All needle valves in Parker’s H series manifold valves have PTFE seats and gland packing as standard, with PEEK seats and graphoil gland packing options.

The needle valves use a standard globe style bonnet design for safe, reliable and repeatable performance. They feature an anti-blowout stem, a self centering, non-rotating spindle tip and an externally adjustable gland. As standard, the needle valves have metal-to-metal seats to ensure 100% bubble-tight shut-off, and PTFE gland packing. Graphoil gland packing and PEEK or PCTFE soft tips for gas applications are available. Further options include anti-tamper spindles, as well as lockable handwheels and T-bars.

Most of the valves and manifolds in this series are manufactured from 316 stainless steel. Oxygen clean, NACE compliant and other types of materials are also available. As standard, the components have a maximum working pressure of 10000 PSI (689 bar). The operating temperature range depends on the type of valve seat and gland packing material that is specified.

Markets:

- Oil and Gas Offshore

- Oil and Gas Onshore

- Petrochemical

- Chemical

Applications:

- Instrumentation lines

- Process isolation

- Topside umbilical termination units

- Hydraulic power units

- Chemical injecttion skids

Features/Benefits:

- Two piece body design – minimal leakage paths

- 4:1 Pressure boundary designed safety factor

- Designed to comply with requirements of ANSI/ASME B16.34 where applicable

- Bi-directional

- Floating ball principal with dynamic response seats featuring inherent self relief

- Integral compression ends available eliminating taper threads and thread sealants

- Low torque operation

- Quarter turn positive stop handle with ergonomically designed protective sleeve

- Full hydrostatic and low pressure air tested

- Anti static

- Optional firesafe designed to meet API 607, BS6755 Pt2.d

Ball Valves

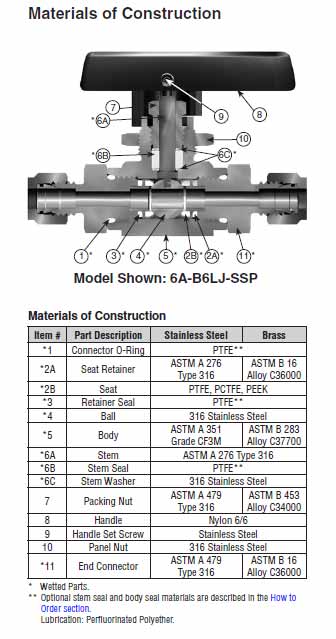

Two-Way B Series Ball Valves

Parker manually, pneumatically, and electrically actuated two-way B Series Ball Valves provide quick 1/4 turn on-off control of fluids utilized in process and instrumentation applications. A broad selection of valve body, seat, and seal materials provide a wide range of pressures and temperatures at which the valve may be used.

Features

- Free floating ball design provides seat wear compensation.

- Available in 316 stainless steel and brass construction. Monel® Alloy 400 and Hastelloy® C-276 construction available upon request.

- Micro-finished ball provides a positive seal.

- Straight through flow path for minimum pressure drop.

- Bi-directional flow.

- Wide variety of US Customary and SI ports.

- 90° actuation.

- Panel mountable.

- Adjustable PTFE stem seal can be maintained in-line.

- Handle indicates flow direction.

- Low operating torques.

- Positive handle stops.

- Color coded handles.

- Optional pneumatic and electric actuation.

- Optional live-loaded PTFE stem seals.

- Optional non-adjustable O-ring stem seals.

- Optional upstream and downstream drain models.

- Optional stainless steel and extended handles.

Two-Way B Series Ball Valves

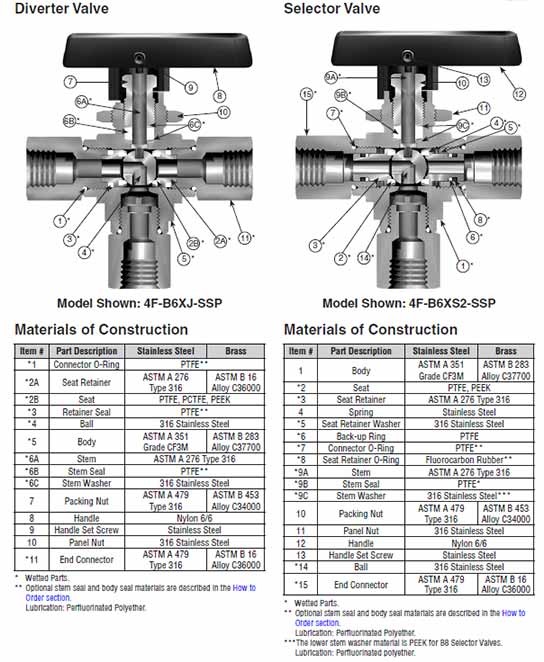

Three-Way B Series Ball Valves

Parker manually, pneumatically, and electrically actuated three-way B Series Ball Valves may be used as diverting or selecting valves for fluids utilized in process and instrumentation applications. The standard three-way diverter valve is designed to accept media through the bottom port and direct it out of two outlet ports. When equipped with spring-loaded seats, the three-way valve may be used as a selector valve, alternately accepting media from either of two inlet sources (side ports) and directing it through a single outlet (bottom port).

Features

- Available in 316 stainless steel and brass construction. Monel® Alloy 400 and Hastelloy® C-276 construction available for Diverter Valves upon request.

- Micro-finished ball provides a positive seal.

- Wide variety of US Customary and SI ports.

- 180 degree actuation.

- Panel mountable.

- Adjustable PTFE stem seal can be maintained in-line.

- Handle indicates flow direction.

- Low operating torques.

- Positive handle stops.

- Color coded handles.

- Optional pneumatic and electric actuation.

- Optional live-loaded PTFE stem seals.

- Optional non-adjustable O-ring stem seals.

- Optional stainless steel and extended handles.

Three-Way B Series Ball Valves

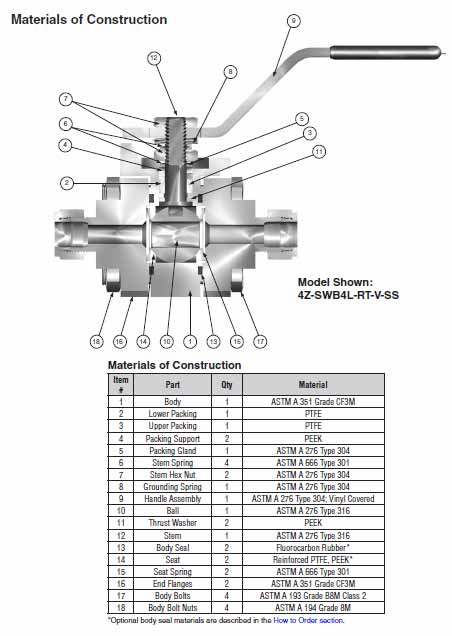

SWB Series Ball Valves

Parker’s three-piece SWB Series Ball Valves are durable valves that can handle the pressure and piping loads. The center section can swing out to quickly and easily replace seats, seals and the ball without major disruption to the piping system.

Features

- Ultra low internal volume

- Free floating ball design allows for seat wear compensation

- Self-compensating stem seal

- Spring-loaded seats

- Blow out resistant stem

- Fully enclosed body bolting

- Four bolt construction

- ISO-type actuator mounting design

- Pneumatic and electric actuation options

- 100% factory tested

SWB Series Ball Valves

Needle Valves

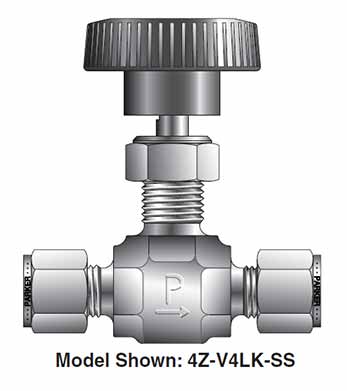

V Series Needle Valves

Parker V Series Needle Valves are designed for positive leak tight shut-off and regulation of fluids in process, power, and instrumentation applications. With a wide variety of port sizes and styles, temperature capabilities ranging from -65°F to 450°F (-54°C to 232°C) and pressures to 5000 psig (345 bar), V Series Needle Valves provide the user with the utmost in flexibility when designing miniaturized tubing or piping systems.

Features

- Choice of three stem types:

R-Stem – All metal, blunt stem tip

N-Stem – All metal, tapered needle stem tip

K-Stem – PCTFE stem tip - Differential hardness between the strain hardened stem and cold formed body threads

provides improved cycle life - Choice of PTFE packing or elastomeric O-ring stem seals

- 316 Stainless Steel, Steel, Brass and Monel® Alloy 400 construction

- Inline and angle patterns

- Wide variety of US Customary and SI ports

- Panel mountable

- 100% factory tested

- Optional color coded handles

V Series Needle Valves

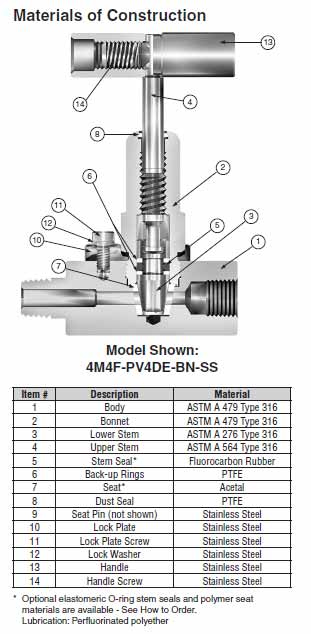

PV Series Rising Stem Plug Valves

Parker Rising Plug and Gauge/Root Valves are available with a variety of seat and seal materials. They are screwed bonnet designs featuring bonnet lock plates. The PV and PVG Series of valves provide a straight-through flow path in two orifice sizes. The valves utilize a non-wetted upper stem and a non-rotating lower stem in conjunction with a tapered seat for positive shut-off and long seat life, even in particulated media.

Features

- Bi-directional flow

- Roddable, straight through flow path

- Bonnet lock plate resists accidental bonnet disengagement

- Stem dust seal helps protect stem from external contamination

- Inlet side optional outlet – PVG 1/4″ Female NPT– PVG 1/2″ Female NPT

- Rugged 316 stainless steel barstock construction

- Panel mounting option

- Gauge port option

- 100% factory tested

PV Series Rising Stem Plug Valves

Valves from Parker Process Analytical Product Line

Excess Flow Shutoff Valve

Parker’s FS190 Series excess flow shutoff valve operates within a wide range of inlet pressures from 10 to 3,500 psig. A non-attitude sensitive valve, FS190 can be used between a high-pressure source at the inlet to the pressure regulator or in low-pressure delivery lines to a process. In both applications, this control valve will automatically shut off delivery of gas should the flow exceed the preset limit.

Product Features:

- Offered with six different pressure / flow limits

- Differential pressure created is not affected by mounting orientation (non-attitude sensitive)

- Actuating knob designed to manually operate valve and clearly indicate relative operating position – Open (Reset) or Auto (Shutoff)

- Pneumatic actuator available to reset the valve remotely

Marine Valves for Industrial Marine Application

Manually Operated Globe Valve – DN15 – 150

The Parker Bestobell range of Stainless Steel, extended globe valves have been designed to eliminate leakages, maximize lifetime operation and reduce maintenance and spares cost for ship operators, whilst providing full compliance with Class requirements. The range is available with either butt weld or flanged options and utilities Parker Bestobell’s unique independent bonnet and flange design, eliminating leakage through the flange gasket. Coupled with a three stage packing at the top of the stem, Parker Bestobell globe valves are leak free to atmosphere.

The floating disc arrangement provides absolute sealing across the seat, and is designed to provide a tight, leak free shut off whilst still providing compliance with fire safe requirements for LNGC applications. Nitronic steel bushings provide smooth operation without galling problems.

Stainless Steel Extended Globe Valve

Product Features:

- Designed and manufactured for use on LNGC, FSRU & FLNG in accordance with BS6364.

- Full range of Class 150 Stainless Steel extended globe valves. Class 300 available for sizes up to DN100.

- Independent bonnet and flange design

- Floating disc arrangement

- Fire safe graphite gasket

- Fire safe all metal seat design

Cryogenic Actuated Globe Valve – Hydraulically Actuated – DN25 – DN350

The Parker Bestobell range of Stainless Steel, extended globe valves have been designed to eliminate leakages, maximize lifetime operation and reduce maintenance and spares cost for ship operators, whilst providing full compliance with Class requirements. The range is available with either butt weld or flanged options and utilities Parker Bestobell’s unique independent bonnet and flange design, eliminating leakage through the flange gasket. Coupled with a three stage packing at the top of the stem, Parker Bestobell globe valves are leak free to atmosphere.

The all metal seat of the valves are designed to provide a tight, leak free shut off against the valve disc and allow compliance with fire safe requirements for LNGC applications. Nitronic steel, also Aluminum-Bronze, bushings provide smooth operation without galling problems.

The valves can be operated by either a linear or multi-turn hydraulic actuator, and both types are used for throttling and on/off applications. Position control is provide either by a potentiometer or with a torque switch, and On/Off actuation is controlled by limit switches.

Hydraulically Actuated Stainless Steel Extended Globe Valve

Product Features:

- Designed and manufactured for use on LNGC, FSRU & FLNG in accordance with BS6364

- Full range of Class 150 Stainless Steel extended globe valves. Class 300 available for sizes up to DN100

- Independent bonnet and flange design

- Firesafe graphite gasket

- Firesafe all metal seat design

- Firesafe graphite, carbon, nitronic steel packing at the top of the stem

- Nitronic steel bushings

- Linear and hydraulic motor type actuators available

- Throttling and On/Off functions available

- Laser etched nameplates

Cryogenic Actuated Globe Valve – Pneumatically Actuated – DN15 – DN150

The Parker Bestobell range of Stainless Steel, extended globe valves have been designed to eliminate leakages, maximize lifetime operation and reduce maintenance and spares cost for ship operators, whilst providing full compliance with Class requirements. The range is available with either butt weld or flanged options and utilities Parker Bestobell’s unique independent bonnet and flange design, eliminating leakage through the flange gasket. Coupled with a three stage packing at the top of the stem, Parker Bestobell globe valves are leak free to atmosphere.

The all metal seat of the valves are designed to provide a tight, leak free shut off against the valve disc and allow compliance with fire safe requirements for LNGC applications. Nitronic steel bushings provide smooth operation without. The valves can be operated for throttling and on/off applications. Position control is provide either by a potentiometer, and On-Off actuation is controlled by limit switches.

Pneumatically Actuated Stainless Steel Extended Globe Valve

Product Features:

- Designed and manufactured for use on LNGC, FSRU & FLNG in accordance with BS6364

- Full range of Class 150 Stainless Steel extended globe valves. Class 300 available for sizes up to DN100

- Independent bonnet and flange design

- Firesafe graphite gasket

- Firesafe all metal seat design

Cryogenic Swing Check Valve – DN25 – DN350

Stainless Steel Swing Check Valve with bolted bonnet. Available with flanged end connections, with easy access to the serviceable parts of the valve. The valves are designed and manufactured for use with LNG, LPG and other flammable gas services. Loose bolted bonnet design allows for thermal expansion and contraction and eliminates leakage at the bonnet gasket.

Shell minimum wall thickness in accordance with B16.34 and optional full material traceability backed by BSEN 10204 3.1/3.2 certification. Flanged end connections to ANSI B16.5 and Butt Weld end connections to B16.25

Stainless Steel Swing Check Valve

Product Features:

- 316 Stainless Steel construction for marine applications

- Internal hinge design

- PTFE seal ensures a tight shut off

- Quick removal of headworks allow fast, easy maintenance

- Temperature range -196°C to + 80°C

- Fire safe approved to BS EN ISO 10497:2004

- ISO 9001 accreditation

- General design in accordance with BS6364

Cryogenic Lift Check Valve – DN25 – DN200

The Parker Bestobell range stainless steel lift check valves have been designed to reduce leakage across the seat, maximize lifetime operation and reduce maintenance and spares cost for ship operators, whilst providing full compliance with Class requirements.

The valve range is available with either butt weld or flanged options designed to ANSI standards, and designed to prevent back flow in LNG systems. Both the valve disc and the metal seat have a final lapped finish to provide the excellent sealing properties across

the seat. The bolted bonnet headworks provides for quick and easy access for maintenance and servicing of the valves.

Stainless Steel Lift Check Valve

Product Features:

- Designed and manufactured for use on LNGC, FSRU & FLNG and LNG fuel systems in accordance with BS6364

- Full range of Class150 stainless steel swing check valves. Class 300 available for sizes up to DN100

- Firesafe all metal seat design

- Lapped valve disc and seat

- Bolted bonnet headworks

- Firesafe graphite gasket

- Laser etched nameplates

Miniature Needle Globe Valve – Bolted Bonnet – Extended and Non-Extended Stem – DN15 – DN25

Stainless Steel extended and non-extended spindle needle globe valve with bolted bonnet and integral metal seat.

Available with socket weld, butt weld and flanged ends, the valve has a

conical seat design for a tight shut off. The bolted bonnet allows for simple site maintenance, with easy access to the serviceable parts of the valve.

Stainless Steel Spindle Needle Globe Valve

Product Features:

- Designed and manufactured for use with LNG, LPG and other flammable gas services

- Temperature range -196°C to + 80°C

- 316 Stainless Steel construction for marine applications

- Fire safe approved to BS EN ISO 10497:2004

- Loose bolted bonnet design allows for thermal expansion and contraction and eliminates leakage at the bonnet gasket

- Anti-blow out stem for operator safety

- Rotating disc prevents galling seat contact and reduces wear

- Quick removal of headworks allows fast, easy maintenance

Screw Down Non-return Valve – Inside Screw – DN25 – DN65

Stainless Steel Extended and non-extended stem globe valve with bolted bonnet and available with socket weld and butt weld ends, the valve is of the cone seat design for drop tight shut off. Unique Parker Bestobell loose flange bolted bonnet design allows for thermal expansion and contraction and eliminates leakage at the bonnet gasket.

The bolted bonnet allows easy maintenance, even in confined spaces with lower bolting torques required than for an equivalent size union bonnet valve. All valves are degreased for oxygen duty, assembled in clean room conditions and pressure tested prior to dispatch. Limit switches available for position indication.

Stainless Steel Stem Globe Valve

Product Features:

- Designed and manufactured for use on LNGC, FSRU & FLNG in accordance with BS6364

- Full range of Class 150 Stainless Steel extended globe valves. Class 300 available for sizes up to DN100.

- Independent bonnet and flange design

- Floating disc arrangement

- Firesafe graphite gasket

- Firesafe all metal seat design

- Firesafe graphite, carbon, nitronic steel packing at the top of the stem

- Quick removal of headworks allow fast, easy maintenance

- Nitronic steel bushings

- Laser etched nameplates

Float Level Isolation Valve – DN200 & DN300

The Parker Bestobell FLIV valve has been bespoke designed to work in conjunction with Whessoe or Henri secondary float level measurement systems, providing secure isolation of the float from the cargo tank. The FLIV eliminates the problems faced with gate valves of accidental cutting of the float tape that results in both tape and float falling back into the cargo tank.

Should the valve be accidentally closed before the float is fully re-wound, then the closing action of FLIV will result in the tape being trapped on the side of the valve disc rather than being cut, preventing the tape and float from falling back into the cargo tank.

The FLIV is operated by a quarter turn gearbox that has a clear open / shut indicator enabling quick and easy checks on the position of the valve disc. The gearbox is also fitted with ‘padlock flanges’ so that the valve can be locked to preventing unauthorized operation.

The compact design of the FLIV means that a single operative can operate both the valve and the level gauge with ease.

An integral inspection chamber is incorporated in the valve design for the inspection and / or replacement if the float, thus eliminating the need for a separate fabricated component. The FLIV is fire-safe by design using graphite gaskets on all external joints and PTFE/metal-to-metal backup on the disc.

Float Level Isolation Valve

Product Features:

- Designed and manufactured for use on LNGC and FSRU

- 316 Stainless Steel construction for marine applications

- Integral inspection chamber

- Easy use handwheel and gearbox

- Padlock to prevent unauthorized operation

- Open/close indication

- Swing disc operation prevents cutting of float tape

Cryogenic HP Manual Globe Valve – Class 2500 (370 Bar) – DN15 – 100 (1/2”- 4”)

The Parker Bestobell range of HP globe valves have been designed specifically for the MAN ME-GI fuel gas systems operating at 320 bar pressure or higher. The range covers all of the necessary manual valve applications within the system.

The range is offered with six CV profiles from 5 USGPM up to 30 USGPM, and three standard body sizes. These will cover both cryogenic and gas phases in the system. Pressure drop can be minimized by selecting the correct CV profile for the system conditions and flow rates. The end connection can then be machined to suit.

The range is available with various size butt weld connections and utilities Parker Bestobell’s unique independent bonnet and flange design that eliminates leakage through the flange gasket. Seat leakage at high pressure is also eliminated through careful lapping of the seat and disc faces.

The valves are available with 400mm extended stem for the cryogenic phase, and short stem for the gas phase or for valves that see low flow conditions in cryogenic service. The smallest body size can be used as an instrumentation valve with NPT connections.

HP Manual Globe Valve

Maximum Working Pressure (MWP) – Up to 370 bar (5366 psi) at -196°C to +80°C

Product Features:

- Unique Bestobell loose flange bolted bonnet design allows for thermal expansion and contraction and eliminates leakage at the bonnet gasket

- Lapped metal-to-metal seat ensures tight shut off at all times

- Valve is fire safe by design

- Designed and engineered specifically for cryogenic service

- Anti-blowout spindle and one-piece high strength design for operator safety

- Precision machined one-piece extension tube cover with integral bush for high pressure use

- Fast/easy maintenance of disc

- Long life carbon and graphite gland packing

- Gearboxes available in marine grade paint for on deck applications

Cryogenic HP Pneumatic Actuated Globe Valve – Class 2500 (370 Bar) – DN15 – 100 (1/2” – 4”)

The Parker Bestobell range of HP globe valves have been designed specifically for the MAN ME-GI fuel gas systems operating at 320 bar pressure or higher. The range covers all of the necessary actuated valve applications within the system and allows end users to select on/off or control valves where necessary.

The range is offered with four CV profiles from 5 USGPM up to 30 USGPM, and two standard body sizes. These will cover both cryogenic and gas phases in the system. Pressure drop can be minimized by selecting the correct CV profile for the system conditions and flow rates. The end connection can then be machined to suit.

The range is available with various size butt weld connections and utilities Parker Bestobell’s unique independent bonnet and flange design that eliminates leakage through the flange gasket. Seat leakage at high pressure is also eliminated through careful

lapping of the seat and disc faces.

The valves are available with 400mm extended stem for the cryogenic phase, and short stem for the gas phase or for valves that see low flow conditions in cryogenic service.

DN50 Pneumatic Actuated Stainless Steel Globe Valve

Maximum Working Pressure (MWP) – Up to 370 bar (5366 psi) at -196°C to +80°C

Product Features:

- Unique Bestobell loose flange bolted bonnet design allows for thermal expansion and contraction and eliminates leakage at the bonnet gasket

- Lapped metal-to-metal seat ensures tight shut off at all times

- Valve is fire safe by design

- Designed and engineered specifically for cryogenic service

- Anti-blowout spindle and one-piece high strength design for operator safety

- Precision machined one-piece extension tube cover with integral bush for high pressure use

- Fast/easy maintenance of disc

- Long life carbon and graphite gland packing

- Actuators available in “fail open” and “fail close” operation

- Actuators available in marine grade paint for on deck applications

Cryogenic HP Pressure Control Valve – Class 2500 (370 Bar) – DN15 – 65 (1/2” – 2 1/2”)

The Parker Bestobell range of HP globe valves have been designed specifically for MAN ME-GI fuel gas systems operating at 320 bar pressure or higher. The HP Pressure Control Valve has been specifically designed to fine control pressure in the main line before and after the evaporator.

The valve is designed to reduce pressure in the main fuel line by safely discharging LNG from 320 Bar to less than 10 Bar. The CV has been significantly reduced to prevent excessive pressure loss in the main fuel line. The valve is supplied with a removable orifice plate so that the CV can be adjusted during commissioning if needed. By adjusting the CV allows for fine tuning of the flow rate and pressure drop though the orifice plate to suit operating conditions.

The HP Pressure Control valve is available with various size butt weld connections to suit the pipe size and utilises Parker Bestobell’s unique independent bonnet and flange design that eliminates leakage through the flange gasket. Seat leakage at high pressure is also eliminated through careful lapping of the seat and disc faces. The valves are available with 400mm extended stem for use in the cryogenic phase.

HP Pressure Control Valve

Maximum Working Pressure (MWP) – Up to 370 bar (5366 psi) at -196°C to +80°C

Product Features:

- Unique Bestobell loose flange bolted bonnet design allows for thermal expansion and contraction and eliminates leakage at the bonnet gasket

- Removable orifice plate to adjust flow and pressure drop

- Discharge cage to reduce sound and cavitation

- Lapped metal-to-metal seat ensures tight shut off at all times

- Valve is fire safe by design

- Designed and engineered specifically for cryogenic service

- Anti-blowout spindle and one-piece high strength design for operator safety

- Precision machined one-piece extension tube coverwith integral bush for high pressure use

- Fast/easy maintenance of disc

- Long life carbon and graphite gland packing

- Actuators available in “fail open” and “fail close” operation

Cryogenic HP On/Off Pump De-Gassing Valve – Class 2500 (370 Bar) – DN15 – 25 (1/2” – 1”)

The Parker Bestobell range of HP globe valves have been designed specifically for MAN ME-GI fuel gas systems operating at 320 bar pressure or higher. The HP De-Gassing valve has been specifically designed for use in the pump startup loop of the HP fuel gas system

to remove pressure from the pump as it builds up system pressure. It is also required to operate during the pump shutdown.

The valve is designed to reduce pressure in the main fuel line by safely discharging LNG from 320 Bar to less than 10 Bar through the return pipe to the LNG tank. The CV has been significantly reduced to prevent excessive pressure loss in the main fuel line. The valve is supplied with a removable orifice plate so that the CV can be adjusted during commissioning if needed. By adjusting the CV allows for fine tuning of the flow rate and pressure drop though the orifice plate to suit operating conditions.

The HP De-Gassing valve is available with various size butt weld connections to suit the pipe size and utilities Parker Bestobell’s unique independent bonnet and flange design that eliminates leakage through the flange gasket. Seat leakage at high pressure is also eliminated

through careful lapping of the seat and disc faces. The valves are available with 400mm extended stem for use in the cryogenic phase.

HP On/Off Pump De-Gassing Valves

Maximum Working Pressure (MWP) – Up to 370 bar (5366 psi) at -196°C to +80°C

Product Features:

- Unique Bestobell loose flange bolted bonnet design allows for thermal expansion and contraction and eliminates leakage at the bonnet gasket

- Removable orifice plate to adjust flow and pressure drop

- Discharge cage to reduce sound and cavitation

- Lapped metal-to-metal seat ensures tight shut off at all times

- Valve is fire safe by design

- Designed and engineered specifically for cryogenic service

- Anti-blowout spindle and one-piece high strength design for operator safety

- Precision machined one-piece extension tube coverwith integral bush for high pressure use

- Fast/easy maintenance of disc

- Long life carbon and graphite gland packing

- Actuators available in “fail open” and “fail close” operation

- Actuators available in marine grade paint for on deck applications

Cryogenic HP Lift Check Valve – Class 2500 (370 Bar) – DN15 – 100 (1/2” – 4”)

The Parker Bestobell range of HP globe valves have been designed specifically for the MAN ME-GI fuel gas systems operating at 320 bar pressure or higher. The range covers all of the necessary check valve applications within the system.

The range is offered with four CV profiles from 5 USGPM up to 30 USGPM, and two standard body sizes. These will cover both cryogenic and gas phases in the system. Pressure drop can be minimized by selecting the correct CV profile for the system conditions and flow rates. The end connection can then be machined to suit.

The range is available with various size butt weld connections and utilities Parker Bestobell’s unique independent bonnet and flange design that eliminates leakage through the flange gasket. Seat leakage at high pressure is also eliminated through careful lapping of the seat and disc faces.

The lift check valves are suitable for use in both cryogenic and gas phases.

HP Lift Check Valve

Maximum Working Pressure (MWP) – Up to 370 bar (5366 psi) at -196°C to +80°C

Product Features:

- Unique Bestobell loose flange bolted bonnet design allows for thermal expansion and contraction and eliminates leakage at the bonnet gasket

- Lapped metal-to-metal seat ensures tight shut off at all times

- Valve is fire safe by design

- Designed and engineered specifically for cryogenic service

- One-piece high strength design for safety

- Precision machined one-piece body and extension tube cover with integral bush for high pressure use

- Fast/easy maintenance of disc

- Vented disc to prevent locking in the open position and ensures fast reaction closing under back pressure.