Channel Track & Tube-Way

These are the products we carry through the manufacturer

Channel Track & Tube-Way.

Condensate Pots

Condensate Pots and Seal Chambers manufactured by Channel-Track & Tube-Way Industries are designed and fabricated in accordance with the Instrument Society of America Publication RP3.

Uses of Chambers

Condensate Chambers are used in the measurement of steam or other vapors which condense to the liquid state at the ambient temperature of the meter. Seal chambers are used in the measurement of fluids which, due to their corrosive or viscous properties, are preferably prevented from entering the meter body. The chambers provide a large area of contact between the measured fluid and the condensate or seal liquid, minimizing errors due to unequal head of fluid in the two connecting lines to the meter.

Construction

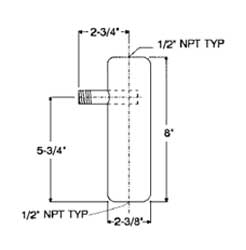

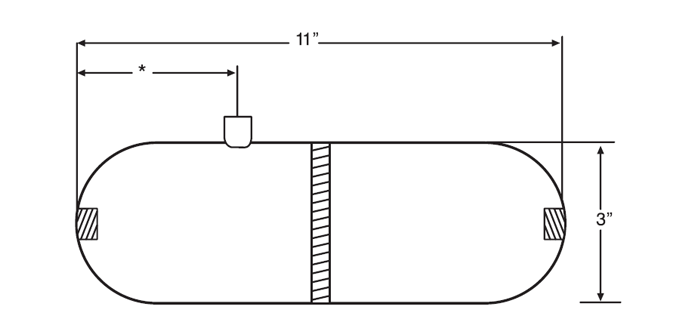

Channel-Track Seal Chambers/Condensate Pots are constructed in three ways; the primary design is to fabricate them of schedule 80 pipe which results in hemispherical ends formed from an intricate heating and spinning/forging manufacturing process. Each end of the vessel is forged with proper thickness to assure full thread engagement after tapping. Side taps are accomplished utilizing 3000 lb. couplings as standard, 6000 lb. couplings are available as an option.

Each unit is rendered free of foreign materials resulting from fabrication; inasmuch as the interior is sandblasted following all manufacturing and preceding hydrostatic testing. The second method of construction is to machine and weld flat plates of proper thickness for threading to each end of the specified proper length and schedule pipe.

The third method of construction is to weld ellipsoidal welding Caps with threaded couplings onto the ends of selected pipe. All of the foregoing methods are in accordance with; the code for pressure piping ASA 8-31.1, latest revision.

2” Catalog No.: CP-1-B-8-N

Testing

Channel Track seal pots are hydrostatically tested at 2500 psig at ambient temperature. Special dimensional, pressure rating, or pressure tap location can be furnished by Channel-Track & TubeWay Industries on request.

Raceway & Cable Tray Systems

For over 40 years, Channel-Track & Tube-Way Industries Inc. has been a leading manufacturer of support systems for instrumentation tubing, wiring, cable and instrument supports.

Products include instrument stands, floor mount or wall mount, single, double and triple upright, in stainless steel or galvanized steel. Channel available in punched angle, channel & flat bar, and connecting parts such as elbow, crosses and tees. Clamping devices are single line clamps, duplex line clamps, gang clamps, and yoke clamps.

Tray Materials

- Stainless

- Aluminum

- Fiberglass

- Galvanized

Punched Angle

Tray Designs

- Perforated Angle

- Channel

- Flat Bar for support of Cable and Instrument Tubing

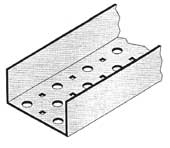

Punched Channel 2” Flange

Instrument Tubing Clamps

- Single-Line Clamp

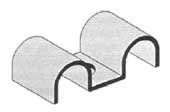

- Duplex Clamp

- Gang Strap & Back Plate

- Yoke Clamp

Duplex Clamp

Yoke Clamp

Protect-O-Way (Raceway)

Protect-O-Way is a pre-engineered protective support system for single tube, multi-tube, electronic and fiber-optic cable. It offers easy, organized, cost efficient installation into power generation and petrochemical plants, water and sewage systems, paper mills or anywhere instrument tubing or cable is installed. The system includes straight sections with covers and a complete line of complementing fittings together with an array of various styles of clamping mechanisms.

Channels are 16’-0” long and 7/8” deep, they come complete with connectors, nuts and bolts and are punched every two (2) feet to accommodate carriage bolts with hold-down clamps or j-bolts. Available in three different materials-6063-T6 aluminum, mill-galvanized steel and stainless steel; Protect-O-Way offers a customized system to satisfy your specific application.

Clamping Devices for Raceway

The various Protect-O-Way clamping devices provide complete flexibility in the use of varying numbers and sizes of cables and tubing.

Stainless Steel Push Clips offer easy installation and firm tube containment by quickly pressing into place at two foot intervals.

The Tube Clip Plate has earned industry approval for a secure clamping action which requires the least field effort of any clamping device. Clip plates are pre-installed at 24” intervals in the supporting channel ready for field use.

Mounting holes at two-foot intervals along the length of the channel permit use of either carriage bolt, hold-down clamp assemblies or J-bolt, hex-nut assemblies. The Hold-Down Clamp assembly may be used for either single or multiple levels of single tube, electronic or multi-tube cable while the J-Bolt Assembly may be used for attaching large diameter cable or multi-tube.

Stainless Steel Push Clips

Tube Clip Plate

Hold-Down Clamp

J-Bolt Assembly