High Pressure Instrumentation

Below are the high pressure instrumentation products that we carry.

Parker is the leading manufacturer of high pressure instrumentation.

Parker MPI™ Medium Pressure Fittings

Parker Hannifin MPI™ Fittings are engineered and manufactured to provide secure, tight, and leak resistant connections throughout industry, including off-shore oil and gas exploration platforms, research labs, and other facilities that require operating pressures in the range of 6,000 to 15,000 psi.

MPI™ Fittings are ideally suited to handle liquids, gases, or chemicals and can be used on a wide variety of tubing materials including cold drawn – 1/8 hard (annealed) tubing or instrument grade thick-walled annealed stainless steel. Every Parker MPI™ Fitting is supplied complete and ready to install.

MPI™ Male Connector

MPI™ Size: 1/4 – 1

NPT Thread: 1/8 – 11.5

Working Pressure (PSIG): 10,000 – 15,000

MPI™ to Female NPT Connector

MPI™ Size: 1/4 – 3/4

NPT Thread: 1/8 – 27

Working Pressure (PSIG): 15,000

MPI™ Bulkhead Union Connector

MPI™ Size: 1/4 – 1

Working Pressure (PSIG): 12,500 – 15,000

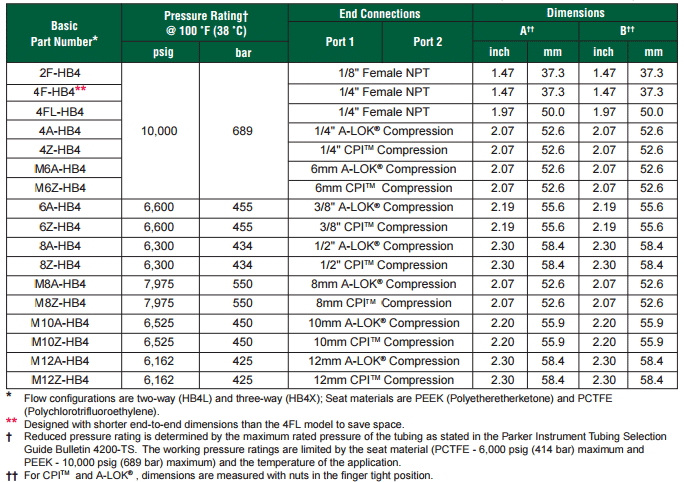

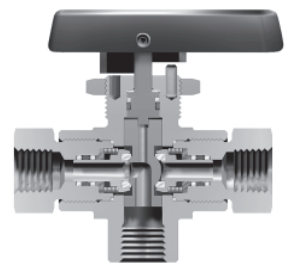

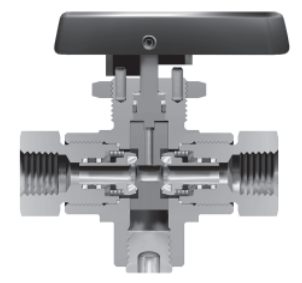

HB Series Ball Valves

Parker High Pressure HB4 Series Ball Valves, featuring SuparcaseTM treated ball and trunnions, provide reliable shut-off or switching functions. The treated trunnion style ball enhances the resistance of the trunnions against seizure and the resistance of the spherical ball to particle abrasion. The compact and rugged design employs spring-loaded seats for high cycle life and low operating torques at pressures up to 10,000 psi (689 bar).

Features

- SuparcaseTM ball/trunnion for longer cycle life

- Two-way and three-way designs

- Compact FNPT version for tight work areas

- Blow-out resistant two-piece ball/stem

- Full operating pressure at any port

- Low operating torque

- Manual, electric or pneumatic actuation

- Panel mountable to 3/8″ (9.6 mm) thickness

- No packing to adjust

- Color coded fracture resistant handles

- Handle indicates direction of flow

- Positive handle stops

- Wide variety of US Customary and SI ports

- Top of stem marked to indicate flow direction

- 100% factory tested

- Compact package

- Heat code traceability

Three-way HB4X design

Two-way HB4L design

Specifications

- Pressure rating: 10,000 psig (689 bar) CWP with PEEK (PKR) Seats; 6,000 psig (414 bar) CWP with PCTFE (K) Seats

- Temperature rating: -65 ˚F to 400 ˚F (-54 ˚C to 204 ˚C)

- Body material: Stainless Steel

- Body configurations: Two-way and Three-way

- Port connections: Tube compression (CPITM / A-LOK®); Short and Long Female NPT

- Port size: 1/8″ – 1/2″ (6mm to 12mm)

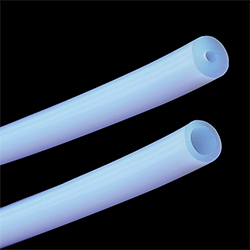

Industrial and Heavy Wall PTFE Tubing

Parker manufactures PTFE tubing, the highest temperature, chemical and corrosion resistance of all the fluoropolymer tubing available, in standard industrial wall and heavy wall designs along with many custom sizes to application requirements. PTFE tubing is the best in temperature and chemical resistance Parker offers and is used in extreme environments.

A PTFE tube has a non-stick surface that facilitates flow and eliminates media buildup. In many cases, it is used to replace glass, rubber and stainless steel because of its chemical and corrosion resistance. In equipment applications, the vibration damping properties of PTFE are excellent at both sonic and ultrasonic frequencies.

Standard and Metric Series i.e. 101 & 201 PTFE tubing respectively, is natural but it is also available with a conductive I.D. or as a fully conductive tube to reduce static discharge. Parflex customer service can help you with selection for custom designs, sizes or colors.

Markets

- Fluid Transfer

- Life Science

- Food and Beverage

Features/Benefits

- Resistant to extreme heat or cold (>-100F to +500F)

- Best chemical and corrosion resistance

- Best flex life of all fluoropolymer/fluoroplastic tubing

- Lowest coefficient of friction of all plastics for easy cleaning

- Non-wetting and non-leaching

- Odorless and tasteless makes it ideal for food and beverage applications

- Resists ultra-violet rays

- Self-extinguishing plastic

Applications

- Chemical/Corrosive applications

- Medical devices

- Analytical instruments

- Food/Beverage processing

- Printing/Marking equipment

- Cryogenic refrigeration systems

- Heat exchangers

Technical Specifications

Product Type– Multiple product types available

Tube O.D. (Inch)– 0.125 to 1.100

Tube O.D. (mm)– 2.4 to 27.94

Tube I.D. (Inch)– 0.031 to 1.000

Tube I.D. (mm)– 0.79 to 25.40

Tube Wall Thickness (Inch)– 0.031 to 0.062

Tube Wall Thickness (mm)– 0.79 to 1.57

Maximum Operating Pressure (psi)– 40 to 390 (dependent on size)

Maximum Operating Pressure (bar)– 3 to 27 (dependent on size)

Minimum Burst Pressure (psi)– 200 to 1950 (dependent on size)

Minimum Burst Pressure (bar)– 21 to 134 (dependent on size)

Minimum Bend Radius (Inch)– 1/2 to 6-1/4

Minimum Bend Radius (mm)– 13 to 305

Minimum Working Temperature (F)– 450

Minimum Working Temperature (C)– 268

Maximum Working Temperature (F)– 500

Maximum Working Temperature (C)– 260

Compatible Fittings– Compression, Compression-Align®, Fast & Tite, TrueSeal

Color– Natural

Tubing Material– PTFE

Industry Standards– AMS 3653E; FDA Compliant; USP Class VI Compliant; RoHs; VW-1, UL-83

Tube Type– Industrial Wall, Heavy Wall, Metric

Application– Fluid Transfer, Food & Beverage, Gas Sampling, High Temperature Applications, Laboratory, Life Science, Heat Exchangers

Media– Adhesives, Chemicals, Water

Standard Pack Quantity (FT)– 25, 50, or 100

Style– Smoothbore

Parker Autoclave Engineers

Parker Autoclave Engineers combines high pressure industry knowledge, manufacturing expertise, and technological innovation to offer a broad range of products and services to customers across a wide range of industries. Their goal is to design, produce and deliver products, systems and solutions that matter while consistently exceeding customer expectations.

- Low Pressure Instrumentation Products to 15,000 psi (1035 bar)

- Medium Pressure Instrumentation Products to 20,000 psi (1380 bar)

- High Pressure Instrumentation Products to 60,000 psi (4135 bar)

- Ultra High Pressure Instrumentation Products to 150,000 psi (10350 bar)

- Air Driven Liquid Pumps and Packaged Systems to 60,000 psi (4135 bar)

Products

- Needle Valves

- Valve Actuators

- Fittings and Tubing

- Adapters/Couplings

- Ball Valves

- Relief Valves

- Custom Valves, Adapters, and Manifolds

High Pressure Needle Valves

Parker Autoclave Engineers high pressure series offer a diverse line of needle valves from 30,000 psi, 40,000 psi, 60,000 psi, to 150,000 psi (10345 bar). This wide selection of valves include many features from various flows and pressures to a full range of tubing sizes for all design requirements.

Features

- Tubing sizes from 1/4″ to 1″.

- Maximum flow areas for valves in high-pressure applications.

- Non-rotating stem prevents stem/seat galling.

- Engineered and designed packing for reliable sealing.

- Metal-to-metal seating for longer seat life and excellent corrosion resistance.

- Vee or regulating tip stem.

- Available in up to five body patterns.

Benefits

Parker Autoclave Engineers high-pressure needle valves are available in seven different series for applications such as the chemical/petrochemical, water-blast, water-jet, research, and oil and gas industries. The Parker Autoclave Engineers high-pressure valve line utilizes a coned-and-threaded connection design providing a leak tight reliable connection for gas and liquid service. These valves are complemented by a complete line of fittings, tubing and accessories.

30SC, 43SC, 30VM, 40VM, 60VM, 100VM, and 150V

Series Needle Valves for operation to 150,000 psi (10345 bar)

MAN Series Needle Valves with MPI™ Style Connections

Parker MAN series needle valves with MPI™ tube connections are designed for multi-turn control of liquid or gas media with regulation or shutoff options for pressures up to 15,000 psi. This Double Ferrule connection delivers fast, easy make-up and reliable bubble-tight performance in either liquid or gas service. Valves are built for MPI™ tube sizes from 1/4″ to 1″ and include five different body patterns providing many control options.

Features

- Valve flow capabilities closely match associated tubing bore sizes.

- CW 316 Stainless Steel Material is Standard, 2507 Annealed Super Duplex as option

- Rising stem/barstock body design

- Non-rotating stem prevents stem/seat galling

- Metal-to-metal seating achieves bubble-tight shut-off, longer stem/seat life in abrasive

- flow, greater durability for repeated on/off cycles, unmatched temperature performance and excellent corrosion resistance

- Temperature range from -423°F (-252°C) to 1000°F (538°C)

- Standard PTFE packing provides dependable stem and body sealing from -423°F to 450°F, additional options include PTFE/Glass (25%) for temperatures to 600°F and Graphite Yarn for temperatures to 1000°F

- Choice of Vee (shutoff) or Regulating Flow Stem Tips

- Replaceable Seat Option available with Right Angle 2-way body style

- Optional N-Dura Stem and Seat Coating or Stellite material option for severe service available

Benefits

MPI™ Connections are designed for both liquids and gases. They can be used on MPI™ 1/8th Hard tubing, Autoclave Engineers Medium Pressure Tubing, or Thick Wall Instrumentation Tubing in both 316 SS and 2507 Super Duplex materials.

- Suparcase® Technology creates a Corrosion Resistant Ferrule set for a strong, mechanical hold

- Double Ferrule design is proven but not interchangeable with standard tube fittings

- Longer Thread Engagement improves resistance to pressure and load on ferrules

- Molybdenum Disulfide Coated Gland Nut prevents galling and makes assembly easier

MAN Series Needle Valve with MPI Connections

MAN Series Needle Valve Extreme Temperature shown with “-VT” (Vent) option

High Pressure Fittings

Parker Autoclave’s high-pressure fitting components are capable of operating to 150,000 psi (10342 bar) and range in size from 1/4″ to 1″ tube size.

Features

- Coned-and-threaded connection

- Tubing sizes are 1/4″, 5/16″, 3/8″, 9/16″, and 1″.

- Fittings manufactured from cold worked 316 stainless steel.

- Operating temperatures from -423ºF (-252ºC ) to 1200ºF (649ºC).

- Available in special materials.

Benefits

Parker Autoclave’s high pressure fittings are used as fluid handling components for the chemical/petrochemical, research, and oil and gas industries and water blast industries. The high-pressure series uses Parker Autoclave’s high-pressure coned and threaded connection. These components provide dependable performance in gas and liquid applications.

PSI

Ultra High Pressure to 150,000 psi

High Pressure to 20,000 psi

Medium Pressure to 20,000 psi

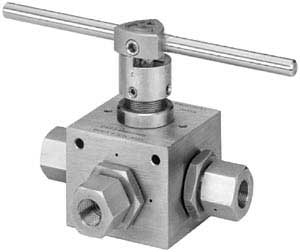

4 Way High Pressure Ball Valves

Parker Autoclave Engineers 4 way ball valve is capable of operating to 10,000 psi (690 bar) and is available in 3/8″ size. Standard ball valves are furnished in 316 SS with specials materials available.

Features

- One piece, trunnion mounted stem design.

- Full port flow path minimizes pressure drop.

- PEEK seats for excellent chemical, heat and wear resistance.

- Available in 90° turn diverter and 180° turn switching models.

- Manufactured from cold worked stainless steel.

- Viton O-rings for operation from 0°F (-17.8°C ) to 400°F (204°C).

- Optional O-rings available for high-temperature service.

- Air and electric valve actuators available.

- Optional wetted materials available.

- Wide selection of tube and pipe end connections.

Benefits

Parker Autoclave’s high-pressure ball valves have been designed to provide superior quality for maximum performance within a variety of valve styles, sizes, and process connections. Our unique design innovations include an integral one-piece trunnion mounted ball and stem that eliminates the shear failure common in two piece designs, re-torqueable seat glands that result in longer seat life, and lower friction stem seal that reduces actuation torque and enhances cycle life.

Pressure Gauges

Pressure vessels which operate under high pressure and cyclic conditions are susceptible to fatigue-related failure. Such failure can result in loss of production and possible personnel safety concerns. Annual inspections are necessary to combat these failure conditions. Parker Autoclave Engineers’ is fully capable of providing these inspection, testing, and re certification services.

Features

- Guard against personnel safety hazards

- Guard against lost production

- Highly experienced, factory trained staff

- Inspections may be performed at our factory or your site

- Technical support from Autoclave’s expert engineering department

- Test equipment traceable to the National Bureau of Standards

- Autoclave can also provide repair, refurbishment, and/or modification of existing vessels

- Annual inspection service scheduling available

Benefits

Safeguard the people and the integrity of your production by performing this critical periodic maintenance on your high pressure equipment. Know that you can rely on the world renowned source of expertise in high pressure equipment, Parker Autoclave Engineers.

Parker Polyflex® Hose Products

Parker Polyflex® carries ultra high pressure products. They’re your complete source for quality tube fittings, hose, hose fittings, brass fittings, brass valves, quick-disconnect couplings, and assembly tools.

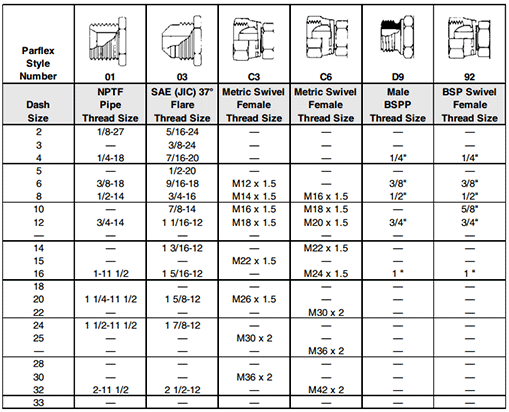

Fittings

These are available in inch metric sizes covering SAE, BSP, DIN, GAZ, JIS, and ISO thread configurations. They’re also manufactured from steel, stainless steel, brass, aluminum, nylon, and thermoplastic.

National Pipe Tapered

(NPT) Male Fittings

PSI: 11,020

JIC Female Swivel Fitting

PSI: 10,000

Couplings

Quick couplings for quick and easy hose assembly connection. Couplings are available in a variety of connection styles with working pressures ranging from 15,000 psi to 30,000 psi.

Rogan series quick couplings are versatile connecting devices that permit easy and rapid joining of hose assemblies to your system. Couplings are available with multiple connection styles, including Type “M”, high pressure, medium pressure and NPT connections. Working pressures range from 15,000 psi to 30,000 psi.

Markets

- Waterblast

- Hydraulics

Features / Benefits

- Working pressures from 15,000 psi to 30,000 psi

- Couplings with check-valves can withstand the full working pressure in the disconnected condition.

- Each coupling is assembled and pressure tested to at least 5,000 psi above its maximum rated working pressure

Applications

- For hydraulic systems and water blast applications ranging from 15,000 to 30,000 psi

Technical Specifications

Coupling Half– Coupler or Nipple (with or without check valve)

Connection Style– Type M”, High Pressure, Medium Pressure, NPT or Low Angle Face Seal”

Thread Type– Male or Female

Connection Size (Inch)– 1/4 to 1

Overall Length (Inch)– 1.98 to 4.64

Overall Length (mm)– 50.29 to 117.860

External Hex (Inch)– .75 to 1.62

External Hex (mm)– 19.05 to 41.15

Flow Diameter (Inch)– .24 or .40

Flow Diameter (mm)– 6 or 10

Maximum Working Pressure (psi)- 15,000 psi – 30,000 psi

Maximum Working Pressure (mpa)– 103 MPa to 207 MPa

Material– Alloy Steel

Hose, Tubing, and Bundles

Available in a wide variety of sizes and materials including rubber, wire-reinforced thermoplastic, hybrid, and custom compounds.

2020N-012 Hose

PSI: 27,550

2040N-04 Hose

PSI: 17,980

McDaniel Controls

McDaniel Controls has numerous styles of high pressure gauges.

Case Styles

4″ (100 mm) Non-Fillable

Model L – 1/4″ NPT

Model M – 1/2″ NPT

PSI Range: 0 – 35,000

6″ (160 mm) Non-Fillable

Model Y – 1/4″ NPT

Model Z – 1/2″ NPT

PSI Range: 0 – 35,000

Mounting Styles

| P |

Panel mount/center back connection (Models S and Q) Panel mount/lower back connection (Models A, C, E, G, B, D, F, H, K) |

| L | Center back connection (Models S and Q) or lower back connection without panel mount flange (Models A, C, E, G, B, D, F, H, K) |

| U | U-Clamp for panel mounting (Center back on S and Q) |

| R | Rear flange for wall-mounting (2½”, 4″, and 6″ gauges only) (Models A, C, E, G, B, D, F, H, K) |